Sectional garage doors are an ideal solution that provides safety and convivence. Consumers have the option to select from a wide range of colours, as well as, add-on equipment based on specific needs. They have an elegant design that incorporates the latest technology and are manufactured to meet all safety regulations and standards in the UK & EU.

Today we are taking a deeper dive into the designs, technology, surveying, fitting and maintenance of those types of doors. We are gonna take a look at 2 different types of doors – OPTIMA and BENEFIT. Buckle up, grab a cup of tea or coffee and let’s go.

SBI Group offers high-quality and easy-to-clean sectional doors. With their fine lines, sectional doors can serve as an added curb appeal to the exterior of a building. Optimal thermal insulation achieved by:

- sandwich panels with a thickness of 40 mm

- side seals

- double seal at the bottom of the door

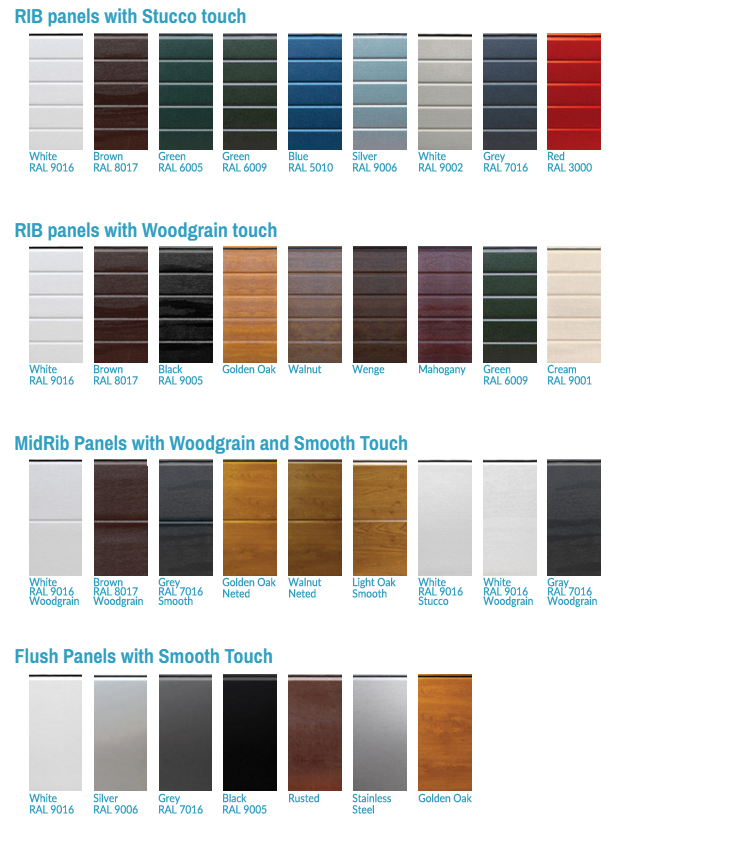

Here we have a diversity of colours and accessories. We have over 40 types of panels with multiple colour options and drawing standards available. There is an option to have glazing within the garage door and an option to incorporate a wicket door.

The first place we will begin is the survey part. This is a crucial moment because you need to evaluate many things and do that correctly so there won’t be any problem with the future door. When you start surveying you need to assess the following: Firstly the application and level of security desired. After that continue to location and access requirements and the number of users. You need to take into account the budget and planning restrictions and lastly the appearance.

The next part is the fitting of the 2 types of doors. There are some differences in the installation process which you can see in the files below. In there you are going to find detailed instructions (a manual) on how to install the doors, what tools are required and much more. Read them carefully.

Sectional doors are manufactured with the highest quality material that guarantees comfort and convenience. The mechanism behind sectional doors ensures safety and silent operation. Efficiency is achieved with these types of doors through vertical openings, which is a space-saving solution. Vertical opening doors are suitable for installation near sidewalks, streets, or larger halls.

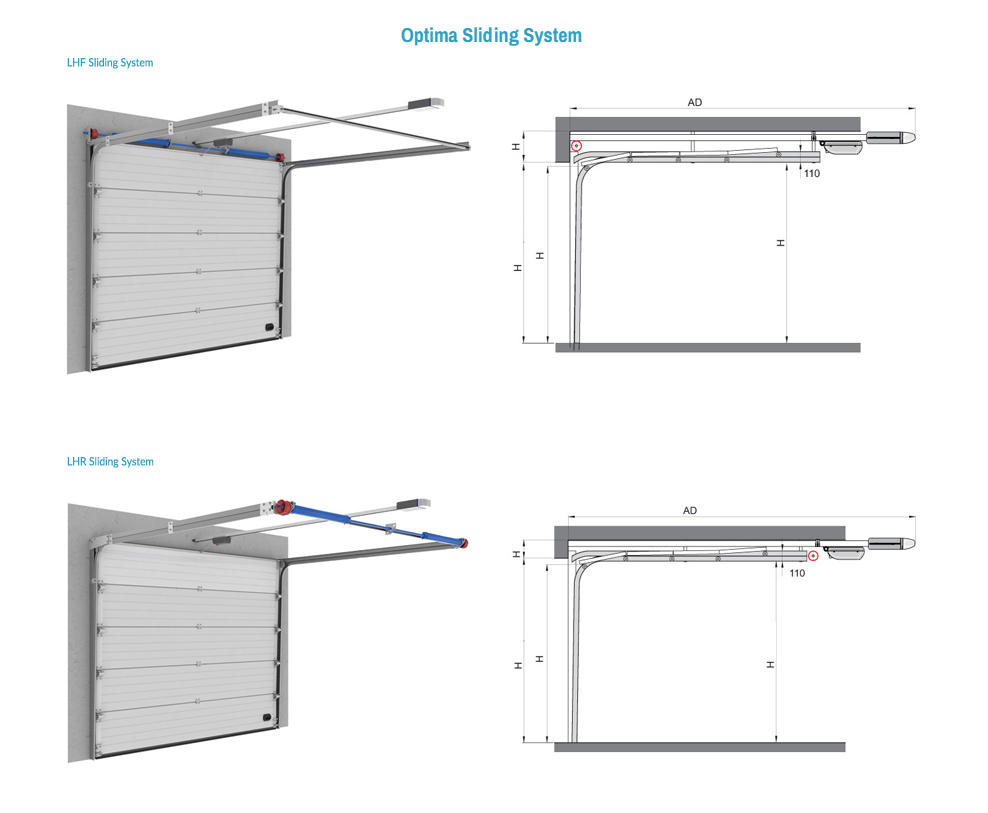

Optima Sectional Garage Doors

- Doors are made to the size of the architect’s design

- LHF – springs are mounted at the front and above the door, on the beam

- LHR – springs are mounted at the back of the door, on the rail

- Hinges and panel caps are painted white

- Torsion springs are guaranteed 25, 000 cycles

- Extended warranty up to 10 years

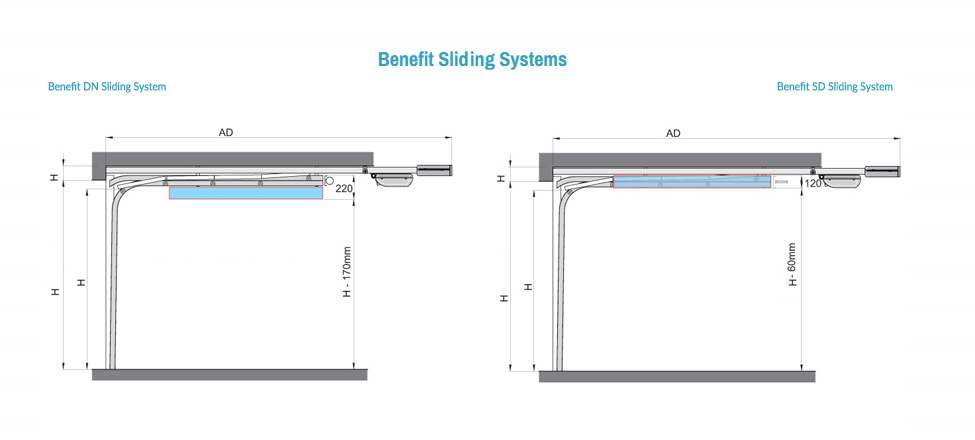

Benefit Sectional Garage Doors

- Doors are made in standard sizes

- SD – springs located on the side of tracks

- DN – springs located under the sliding track

- Traction springs are guaranteed 15, 000 cycles

- Extended warranty up to 5 years

Maintaining your garage door is the most important aspect of its long-term use without any problems. That is why we are dedicating a section to it in which we will explain everything. Let’s divide it into categories so it’s easier to visualise when and what to do.

Immediately after installation

The installer is responsible for this maintenance part.

- Lubrication of the sliding system (tip: spraying with PTFE spray).

- Lubricate the wheels and their axles (tip: spraying with PTFE spray).

- Lubrication of the hinges-intermediate and side (tip: spraying with PTFE spray).

- Lubricate the seals (tip: vaseline for rubber).

After 3 months

The installer is responsible for this maintenance part.

- Checking whether the strips hold the door in an equilibrium position (spring tension).

- View of the door.

Every 6 months or every 750 open/close cycles

The user is responsible for this maintenance part.

- Inspect side, top and bottom seals for wear or abrasion.

- Lubrication of the sliding system (tip: spraying with PTFE spray).

- Lubrication of wheel bearings and axles (tip: spraying with PTFE spray).

- Lubrication of the hinges-intermediate and side (tip: spraying with PTFE spray).

- Lubricate the seals (tip: vaseline for rubber).

- Cleaning the panels (tip: car wax with wax)

- Removing dirt from the door

Every 12 months or every 1500 open/close cycles

The installer is responsible for this maintenance part.

- Check for fraying or fraying of the cables and their ends, as well as the lower hinges

- Check whether the door is in a balanced position and readjust it if necessary. Engine check

- Inspect the hinges for wear or damage

- Check the wheels for wear or chafing

- Check traction springs engagements

- Checking the closing force of the door

- Inspection of ceiling mounting brackets

- Inspect secondary seals for wear or abrasion

- Inspect the bottom seal for wear or abrasion

- Inspect panel seals and top seal for wear or chafing

Today we took a look at Domestic Sectional Doors in the designs, technology, surveying, fitting and maintenance. For more information, you can always contact us or leave a comment down below!