Welcome to our weekly blog post. In today’s post, we are showcasing our industrial roller door in a before and after case study. Stay tuned and enjoy the reading.

Challenges and objectives

Ease of operation

The challenge

The difficult process of opening and closing the door is due to the old school mechanism technology. One of the employees who has been working for 12 years said:

“I wasn’t looking forward to my working days as I had to deal with the opening and closing of the heavy manual roller shutter every single day. Thanks to SBi Group now we have a fully automated roller shutter that provides comfort and security.”

Objective

SBi’s objective is to provide modern roller doors that are easy and safe to operate.

Security

The challenge

Current business stores vehicles overnight as they are providing mechanical service – security factor was a priority on a budget.

Objective

Advise partners and customers in order to provide the best security option for the budget at hand.

Safety

The challenge

The business in question has a couple of employees who operate the old roller shutter many times per day. This increases the possibility of an accident. Employees aren’t working in the best possible security environment.

Objective

Advise partners and customers in order to provide the best safety option for the budget at hand.

Design

The challenge

As a business that operates in modern times, the roller door is the first thing that represents their brand and would reflect their professional service.

Objective

Provide a design that meets all important factors as ease of operation, security, safety and modern appeal.

Safety and security

The first thing that comes up is the bad shape of it. The gap to the left is for a wicket door which brings more negatives than positives. The most important predicament is the disruption of the integrity of the whole roller door. The wicket door compromises the whole purpose of safety and security. If a wicket door is a necessity, our professional advice is to use it in a sectional door.

Guide profiles

The old industrial roller door uses steel “C” profiles where many dents and digs from the operation during the year obstruct the smooth operation of the curtain.

Our system uses “omega” profile guides with noise reduction technology which cannot hold debris and doesn’t require greasing. Moreover, it provides a better security factors than most competitors on the market.

Box covers

The old roller door is missing the box covers which makes the whole moving mechanism exposed – reducing the safety, as well as the appeal of the roller door. This is not optimal. If the mechanism isn’t hidden it can lead to damages and problems. This is why our roller doors come with “Elegant” box covers as standard. They are compactly wound into a well-designed shutter box which requires minimum space. To increase efficiency and provide more space, the box is installed above the light opening. Having a box cover will prevent damages and problems or in odd scenarios birds nesting in the moving mechanism.

Balancing mechanism

The old door was being held by two springs and one of them was broken. If the other one has failed at some point the whole door could have come down and injured someone. Luckily, our industrial doors are supplied with six or more springs to guarantee safety and ease of operation.

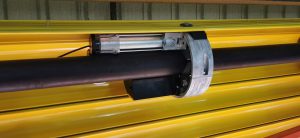

Operation

In most cases, our industrial roller doors are powered by Somfy central motor which provides reliability, high security and easy operation in case of power failure. The combination of the central motor and the springs balances the door to perfection and increases the lifespan of the product. Moreover, the end limits can be adjusted easily with the help of the Somfy adjust tool which makes the whole process very efficient.

Design

SBi Group offers a design that eliminates the difficult process of manual operation and transforms it into a smooth automated joy. We use technologies that offer the best possible security and safety features without breaking the bank. Moreover, our steel industrial roller doors are galvanised, covered by a powder-coated finish, striving for a long-lasting result that best suits your brand.

With the new door comes new opportunities. You can include safety sensors like a safety edge, photocells, warning lights and much more in order to protect your colleagues and staff.

With this, we conclude our case study. Hope you liked it and stay tuned for more in the future. If you believe your business needs an upgrade do not hesitate to contact us.